Ọkpụkpọ Ụkpụrụ Igwe Igwe Ọdụdọ Igwe Igwe Igwe Ọdụdọ Na-enweghị Mmasị Carbon

Nkọwa

A na-eji ọkpọkọ igwe anaghị agba nchara eme ya site na 'billet' ígwè siri ike gburugburu nke a na-ekpo ọkụ na ịkwanye ma ọ bụ dọpụta ya n'ụdị ruo mgbe a ga-eme ka ígwè ahụ ghọọ tube dị oghere.A na-emezi ọkpọkọ enweghị nkebi ka ọ bụrụ nkọwapụta nha na nha mgbidi n'ogo site na 1/8 inch ruo 32 inch OD.Carbon Steel enweghị nkebi Pipes / tubes Carbon steel bụ alloy nke nwere ígwè na carbon.Pasent nke carbon dị na nchara na-emetụta ike, ike nke elasticity na ductility nke carbon steel.A na-eme ọkpọkọ carbon steel nke na-enweghị ntụpọ ma ọ bụ ingot nchara siri ike site na tube capillary site na oghere ahụ, wee site na ọkụ na-ekpo ọkụ, akpọrepu oyi ma ọ bụ oyi.Ọkpụkpọ carbon steel na-enweghị ntụpọ na ụlọ ọrụ igwe China nwere ọnọdụ dị mkpa.Ihe na-enweghị nkebi nke carbon steel bụ ọkpọkọ okirikiri, igwe na-egbutu ọkpọkọ embrayo na-aga site na ịcha ihe dị ka 1 m n'ogologo oghere, wee zite ya site na ikpo ọkụ ọkụ na-ebufe eriri.A na-etinye Billet n'ime ọkụ ọkụ, okpomọkụ dị ihe dịka 1200 degrees Celsius.Mmanụ bụ hydrogen ma ọ bụ acetylene.Ijikwa okpomọkụ ọkụ bụ isi okwu.Gburugburu tube pụtara ịkụ ọkpọ n'igwe site na nrụgide ikuku.Ohaneze ọzọ nkịtị ntụmadị na tapered mpịakọta perforation igwe, na Punch elu mmepụta arụmọrụ, ngwaahịa àgwà, nnukwu dayameta oghere mgbasa, nwere ike na-eyi a dịgasị iche iche nke ígwè.Perforation, gburugburu tube anọwo na mpịakọta mpịakọta atọ, na-atụgharị ma ọ bụ extrusion.Wepụ tube ahụ ka emechara ya.Ịhazi oghere dị elu rotary cone n'ime billet iji mepụta tube.Dayameta ọkpọkọ site na igwe igwe ihe iji chọpụta ogologo dayameta akuakuzinwo.Mgbe ọkpọkọ site na sizing n'ime ụlọ elu dị jụụ, na-eme ka mmiri dị jụụ, nchara mgbe ọ dị jụụ, kwesịrị ịgbatị.Mgbe eriri igwe ezigara site na ịgbatị igwe nnwale igwe (ma ọ bụ ule nrụgide) maka nnwale n'ime.Ọ bụrụ na ọkpọkọ dị n'ime ya gbawara, afụ na nsogbu ndị ọzọ ga-achọpụta.Mgbe ọkpọkọ ma site na nlezianya njikwa njikwa ntuziaka nhọrọ.Ogo ígwè, iji nọmba agba agba, nkọwapụta, ọnụ ọgụgụ mmepụta ihe.Site kreenu n'ime ụlọ nkwakọba ihe.

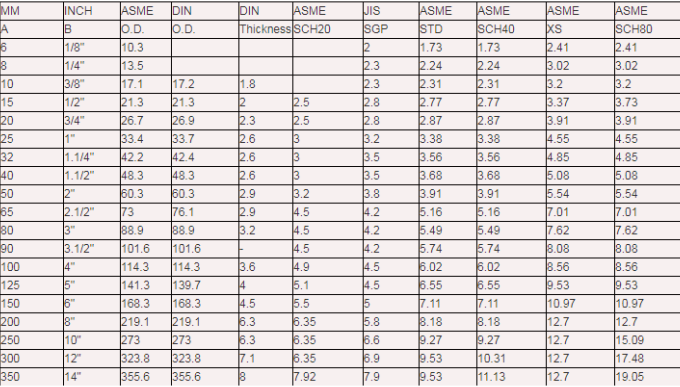

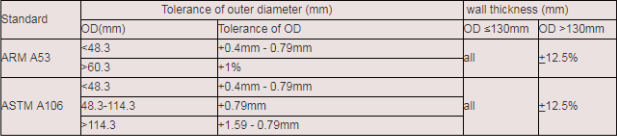

Mgbidi ọkpụrụkpụ nke ọkpọkọ enweghị nkebi

Nkwenye nke dayameta dị n'èzí na ọkpụrụkpụ mgbidi

Nkọwapụta

| Ọkọlọtọ | Nkọwa |

| ASTM A179/A179M | Igwe ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-enweghị ntụpọ na tubes condenser. |

| API 5L | Ọkpụkpọ ahịrị. |

| ASTM A53M | Black & Zinc mkpuchi welded na enweghị ntụpọ. |

| ASTM A106M | Ọkpụkpụ carbon ígwè na-enweghị ntụpọ maka ọrụ okpomọkụ dị elu. |

| ASTM A105M | Carbon ígwè forgings maka ọkpọkọ ngwa. |

| ASTM A234M | Ngwakọta ọkpọkọ nke carbon ígwè arụpụtara arụ ọrụ na ígwè alloy maka ọrụ na-agafeghị oke na oke okpomọkụ. |

Ọkọlọtọ

| Ọkọlọtọ | Ụdị ọkpọkọ | Klas | Ọkwa |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q | ||

| PLS2 gburugburu gburugburu | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS | ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, |

| Ọkọlọtọ | Ọkwa |

| ASTM A53 M | A, B |

| ASTM A106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Ọkwa: Ngwakọta kemịkalụ (%):

| Ọkọlọtọ | Ọkwa | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Ihe osise & mkpuchi

Ngwọta dị n'elu nke ọkpọkọ ígwè: Iji meziwanye ndụ ọrụ nke pipeline mmanụ, a na-emekarị ọgwụgwọ elu iji kwado nchikota siri ike nke ọkpọkọ ígwè na mkpuchi mgbochi. edemede anọ.

1.Cleaning Grease, uzuzu, mmanu, organic okwu na-arapara n'elu nchara ígwè, na-emekarị na-eji ihe mgbaze, emulsion ihicha n'elu. Otú ọ dị, nchara, oxide akpụkpọ na ịgbado ọkụ slag n'elu nke ígwè ọkpọkọ enweghị ike wepụ. ya mere a na-achọ ụzọ ọgwụgwọ ndị ọzọ. Ngwá ọrụ nchara wepụ ígwè ọkpọkọ elu oxide, nchara, ịgbado ọkụ slag, nwere ike iji ígwè waya ahịhịa ọcha na polishing elu ọgwụgwọ.

2.Tool derusting nwere ike kewaa n'ime akwụkwọ ntuziaka na ike, akwụkwọ ntuziaka derusting ngwá ọrụ nwere ike iru Sa 2 larịị, ike ngwá ọrụ derusting nwere ike iru Sa3 level.Ọ bụrụ na elu nke ígwè ọkpọkọ na-agbakwunyere na a karịsịa ike oxide akpụkpọ, ọ nwere ike na-agaghị ekwe omume wepụ. nchara na enyemaka nke ngwaọrụ, ya mere, anyị kwesịrị ịchọta ụzọ ndị ọzọ.

3.Pickling Common pickling ụzọ na-agụnye kemịkalụ na electrolysis.Ma naanị chemical pickling na-eji maka pipeline corrosion protection.Chemical pickling nwere ike nweta a ụfọdụ ogo nke ịdị ọcha na roughness n'elu ígwè ọkpọkọ, nke bụ adaba n'ihi na ụdi arịlịka lines.Usually dị ka. a gbara (aja) mgbe reprocessed.

4.Shot gbawara maka nchara mwepụ.By elu ike moto na-anya ụgbọ elu na-agbagharị agbagharị agụba, ígwè grit, ígwè ogbugba, nkebi, mineral na ndị ọzọ abrasive waya n'okpuru edinam nke centrifugal ike na ígwè anwụrụ elu ịgba na uka ejection, nke ọma wepụ. nchara, oxides na unyi n'otu aka, n'aka nke ọzọ, ígwè anwụrụ n'okpuru omume nke abrasive-eme ihe ike mmetụta na esemokwu ike, iji nweta chọrọ edo roughness.Among anọ ọgwụgwọ ụzọ, gbawara agbawa na derusting bụ ezigbo ọgwụgwọ usoro maka. ikpochapụ ọkpọkọ.N'ozuzu, a na-ejikarị ịgba ọkụ na-agbawa agbawa na derusting maka ọgwụgwọ n'ime elu nke ígwè ọkpọkọ, na ogbugba ogbugba na derusting ka a na-ejikarị maka ọgwụgwọ elu elu igwe.

Mbukota & Ibu

Ịgba agba

Nkwakọ ngwaahịa enweghị mmiri